We offer custom industrial chillers to meet your specific dairy processing needs, from compressor configuration to smart controls. Below are the key customization options available:

Customization Area | Available Options | Purpose / Benefit |

Compressor | - Scroll, screw, or piston type- High/low ambient start kit- Multi-stage or parallel compressors | Match load requirements and adapt to different climate conditions |

Refrigerant | - Eco-friendly: R-32, R-407C, R-410A- Traditional: R-22, R-134a, R-404A- Refrigerant charge, leak detection, recovery support | Meet environmental regulations and ensure safe operation |

Temperature | - Ultra-low temperature down to -15°C- ±0.5°C stability under full load- Integrated sensor & alarm system | Ensure accurate milk cooling, storage, and fermentation control |

Evaporator | - Stainless steel plate type- Shell & tube, surface type- Coil-in-tank option- Easy-clean removable plate covers | Adapt to space limitations and hygiene standards in dairy plants |

Smart Control System | - Touchscreen interface- Real-time monitoring & alarms- Historical data logging- Multi-language support | Enhance usability, remote monitoring, and process traceability |

1. Compressor Customization

Customize the compressor type and compressor stage according to dairy chiller load requirements.

Scroll, screw or piston type compressor

High/low ambient start kit

Multi-stage or parallel combination of compressors

2. Refrigerant Customization

We also provide you with flexible refrigeration solutions to comply with local environmental policies and requirements.

GWP refrigerant (R-32, R-407, R-410)

Traditional refrigerant (R-22, R-134a, R-404A)

Refrigerant charge, Refrigerant treatment, and leak detection and recovery equipment

3. Temperature Customization

An accurate milk cooling and storage temperature option according to your process requirement.

Ultra low temperature chiller

Ultra low temperature down to -15 degree can be customized. Integrated temperature sensor and alarm. Temperature stable ±0.5°C during all load conditions

4. Evaporator Customization

Select the suitable type and configuration of evaporator according to the available space and cooling capacity.

Stainless Steel plate type heat exchanger, surface type, shell and tube or coil in tank evaporator, plate heat exchanger can be cleaned by removing the cover and inspection.

5. Evaporator Customization Smart Controller Options

Increase your control capability and monitoring capability over distance with an intelligent digital control board.

Smart Control Real time system monitoring and alarm on touch screen Historical data logging of performance on touch screen Multi language interface

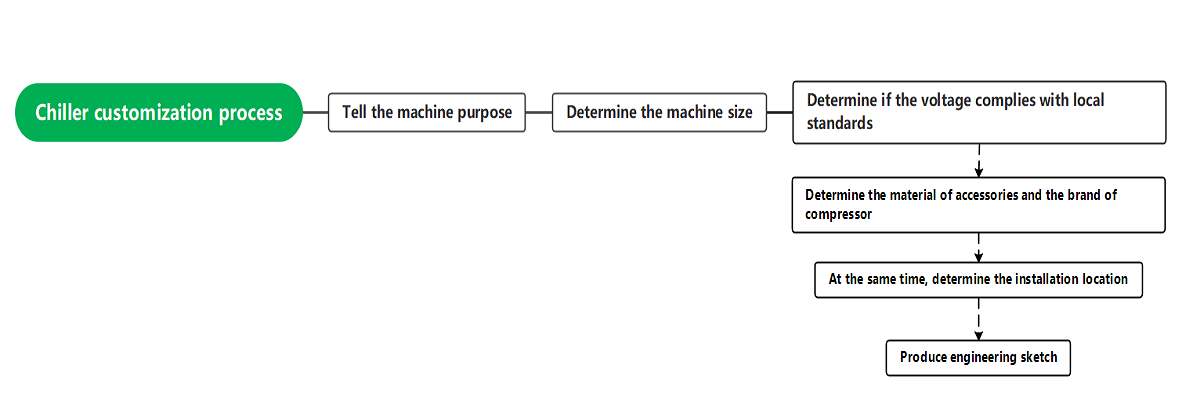

Choosing the right industrial chiller starts with understanding your application scenario and the site conditions. The more accurate your requirements, the more optimized your solution will be — both in performance and cost.

Step 1: Define Your Cooling Needs

Key Question | Example Answer |

What will you cool? | Milk / Mold / Process water |

Desired outlet temperature? | e.g. 4°C |

Flow rate needed (L/h)? | e.g. 1000 L/h |

Installation environment? | Indoor / Outdoor |

Special control requirements? | PLC / Remote Monitoring / Alarms |

Understanding these parameters will help determine the correct chiller type, cooling capacity, and control configuration.

Step 2: Calculate Cooling Capacity

Cooling capacity is expressed in kW, kcal/h, or BTU/h, and is crucial for proper chiller sizing.

If it's too complex, just tell us your parameters — we'll help you calculate.

Example:

To cool 1000 liters of milk from 35°C to 4°C within 1 hour, you'll typically need 10–12 kW cooling capacity.

Cooling Capacity Formula (with Explanation)

Formula:

Cooling Capacity (kW) = Flow (L/h) × Specific Heat × Temperature Drop ÷ 860

Where:

Parameter | Description |

Flow (L/h) | Volume of fluid to be cooled per hour |

Specific Heat | 4.186 (for water) |

Temperature Drop | Inlet Temp − Outlet Temp (°C) |

860 | Conversion factor (to kW) |

Step 3: Confirm Basic Technical Requirements

Parameter | Example / Options |

Required temp range | 5 – 15°C |

Cooling fluid type | Water / Water-Glycol |

Flow rate | e.g. 60 L/min or 3.6 m³/h |

Power supply | 380V / 3PH / 50Hz |

Installation space | Dimensions available |

Control type | Mechanical / Microcontroller / PLC |

These inputs help us design an efficient, energy-saving, and cost-effective solution tailored to your operation.

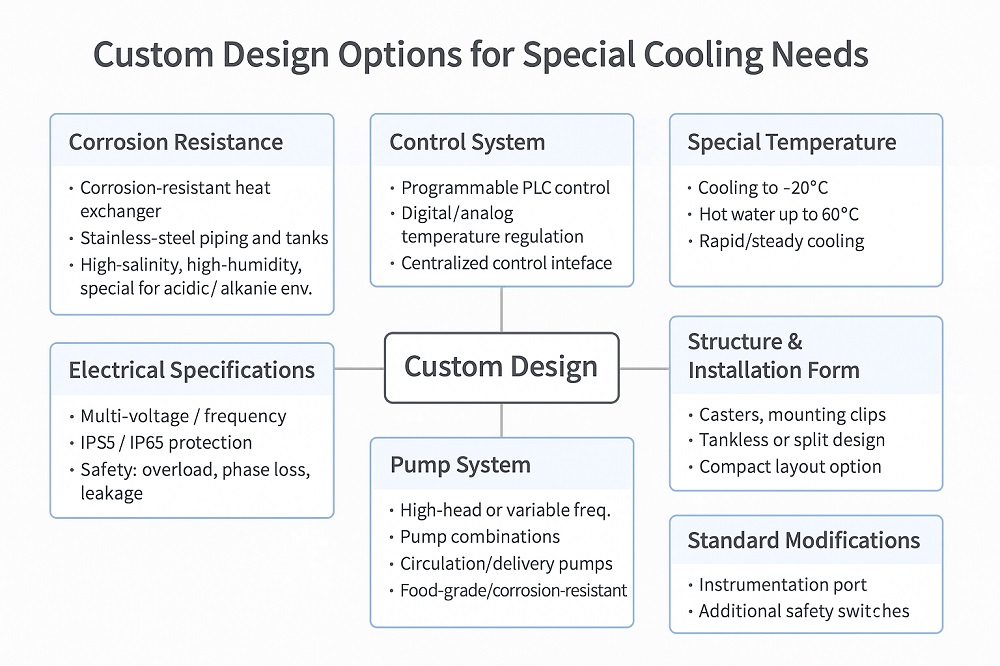

Pengqiang chillers can be fully customized based on your industrial environment, cooling medium, control system, temperature range, and installation requirements.

Corrosion-resistant heat exchangers

Stainless steel piping and tanks

Suitable for high-salinity, high-humidity, or acidic/alkaline environments

Programmable PLC control

Digital or analog temperature regulation

Centralized interface for multi-unit coordination

Cooling down to -20°C for low-temperature applications

Hot water outlet up to 60°C

Fast cooling or stable temperature holding

Multi-voltage / frequency support (global standards)

IP55/IP65 protection for control cabinets

Comprehensive safety: overload, phase loss, leakage protection

High-head or variable frequency pumps

Pump combinations for multiple chillers

Circulation + delivery dual-function pumps

Food-grade or corrosion-resistant pump materials

Casters, mounting clips, or fixed frames

Tankless or compact split design for limited space

Custom layout for tight or mobile setups

For quicker delivery and lower costs, our standard chillers can be customized with:

Extra instrumentation ports

Additional safety switches (low flow, high/low pressure, temperature alarms, etc.)