Our dairy chiller for sale is purpose-built to meet the unique demands of milk cooling, yogurt production, cheese processing, and other dairy applications. Designed for rapid cooling and energy efficiency, our solutions help dairy processors safeguard product freshness, flavor, and safety from pasteurization through storage.

Our dairy chillers are engineered to:

Prevent bacterial growth through precise temperature control during fermentation and storage

Ensure consistency and product quality in cheese, yogurt, and dairy production

Optimize operational efficiency with stable, energy-efficient performance

Our dairy chillers are designed to support a wide range of applications in milk and dairy processing facilities, including:

Milk Cooling after Pasteurization

Yogurt Production Line Cooling

Milk Storage Tank Cooling Systems

Cold Chain Preparation for Transportation

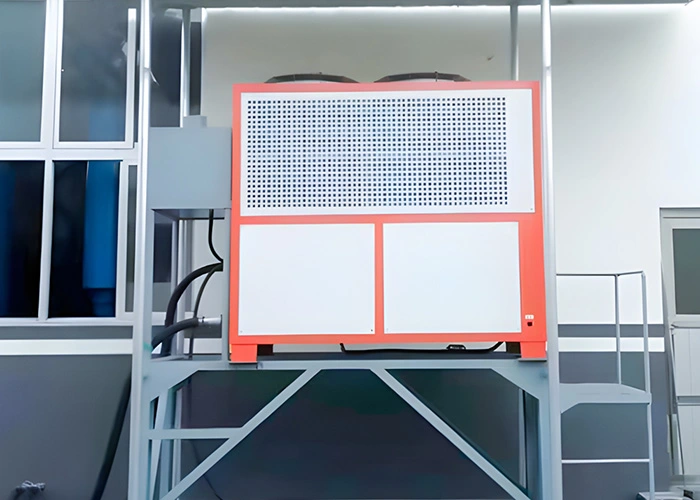

Whether you operate a small-scale dairy or a large industrial plant, Pengqiang, as one of the most professional industrial chiller manufacturers, offers cooling solutions tailored to your needs.

Precise Temperature Control: Stable and reliable cooling from 0°C to 10°C.

Energy Efficiency: Optimized design reduces operating costs.

Food-Grade Construction: Anti-corrosion materials ensure sanitary operation.

Compact & Flexible Design: Suitable for various installation environments.

Reliable Performance: Suitable for continuous 24/7 industrial operation.

Customizable Options: Tailored capacities, fluids, and controls available.

Can be used as a sub-zero low-temperature machine

To support various scales of dairy operations—from small batch milk cooling to large-scale continuous processing—PQZILI offers a wide range of industrial chiller models. Whether you need compact air-cooled units or high-capacity water-cooled systems, we have solutions tailored to your specific dairy cooling needs. Below are three of our most popular models specifically tailored for dairy applications:

Model | Cooling Capacity | Cooling Type | Typical Dairy Application |

PQ-ZL10A | 10HP | Air-Cooled | Small to mid-sized dairy lines, milk tank cooling |

PQ-ZL15A | 15HP | Air-Cooled | Mid-to-large dairy operations with air cooling preference |

PQ-ZL15W | 15HP | Water-Cooled | High-load, temperature-sensitive dairy processing environments |

Tailored Capacity | Custom | Tailored solutions for specific cooling demands in dairy plants |

Pengqiang dairy chillers are engineered to rapidly cool milk during processing and storage, ensuring optimal product quality and hygiene. The system operates by circulating a chilled water or glycol-water solution through a heat exchanger—typically a plate heat exchanger (PHE).

Milk passes through one side of the stainless steel plates.

The chilled glycol-water mixture circulates on the opposite side.

Heat is efficiently transferred through the plate surfaces, reducing the milk temperature to 0–4°C within seconds.

This rapid cooling process is critical for inhibiting bacterial growth, maintaining milk freshness, and complying with strict dairy industry safety standards.

Factory-Direct Advantage

When you work with Pengqiang, you benefit from direct-from-factory pricing with no middleman, ensuring competitive costs and transparent service.

Strong Production Capacity

Our 15,000㎡ manufacturing base delivers up to 800 units per month, enabling fast delivery with reliable inventory and short lead times.

Tailored Cooling Solutions for Dairy Applications

Every dairy operation is unique. We offer customizable chiller solutions to meet all your cooling needs in the dairy processing industry

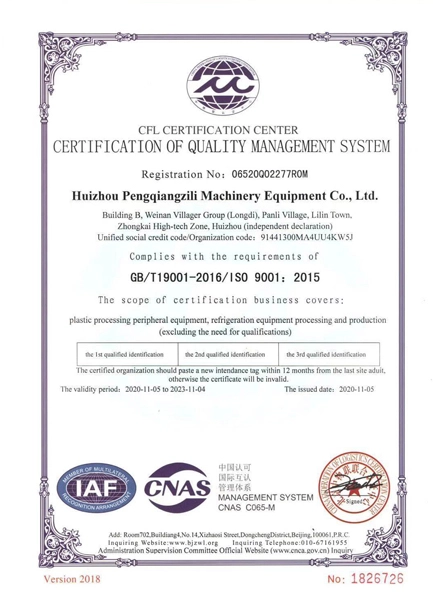

Proven Expertise You Can Trust

With rich industry experience and technical know-how, Pengqiang provides precision-engineered systems designed to meet the high standards of dairy production.

Reliable After-Sales Support

Our service doesn't stop after delivery. We provide warranty coverage, readily available spare parts, and professional technical support to keep your operations running smoothly.

Global Reach, Local Care

Pengqiang supports dairy manufacturers worldwide. We welcome you to visit our facilities and see firsthand how we can help optimize your dairy cooling processes with dependable, efficient solutions.

Chillers are essential equipment in the dairy industry, ensuring precise temperature control throughout the production process—from raw milk cooling to pasteurization, fermentation, and packaging.

Raw Milk Cooling

Chillers rapidly reduce milk temperature after collection, helping prevent bacterial growth and preserve nutrients, which is vital for product safety and shelf life.

Pasteurization Support

After heat treatment, milk must be quickly cooled to maintain flavor and nutritional value. Chillers provide consistent low-temperature water to optimize this step while saving energy.

Fermentation Control

Products like yogurt and cheese require stable, low temperatures during fermentation. Chillers help achieve optimal flavor, texture, and consistency.

Packaging and Cold Chain

Post-packaging, rapid chilling prevents contamination and deterioration. Chillers also support cold storage and transport, maintaining a reliable cold chain across the supply process.

Modern dairy chillers not only improve efficiency and reduce product rejection rates but also use eco-friendly refrigerants and energy-saving designs, aligning with sustainability standards in the food industry.